Pfeiffer & May

Size:

30 000 sqm

Program:

Logistic center

Location:

Karlsruhe, Germany

Status:

Finished

Category:

Architectural identity, sustainability and circular economy were some of the main objectives in the realization of this project alongside a well-functioning logistics.

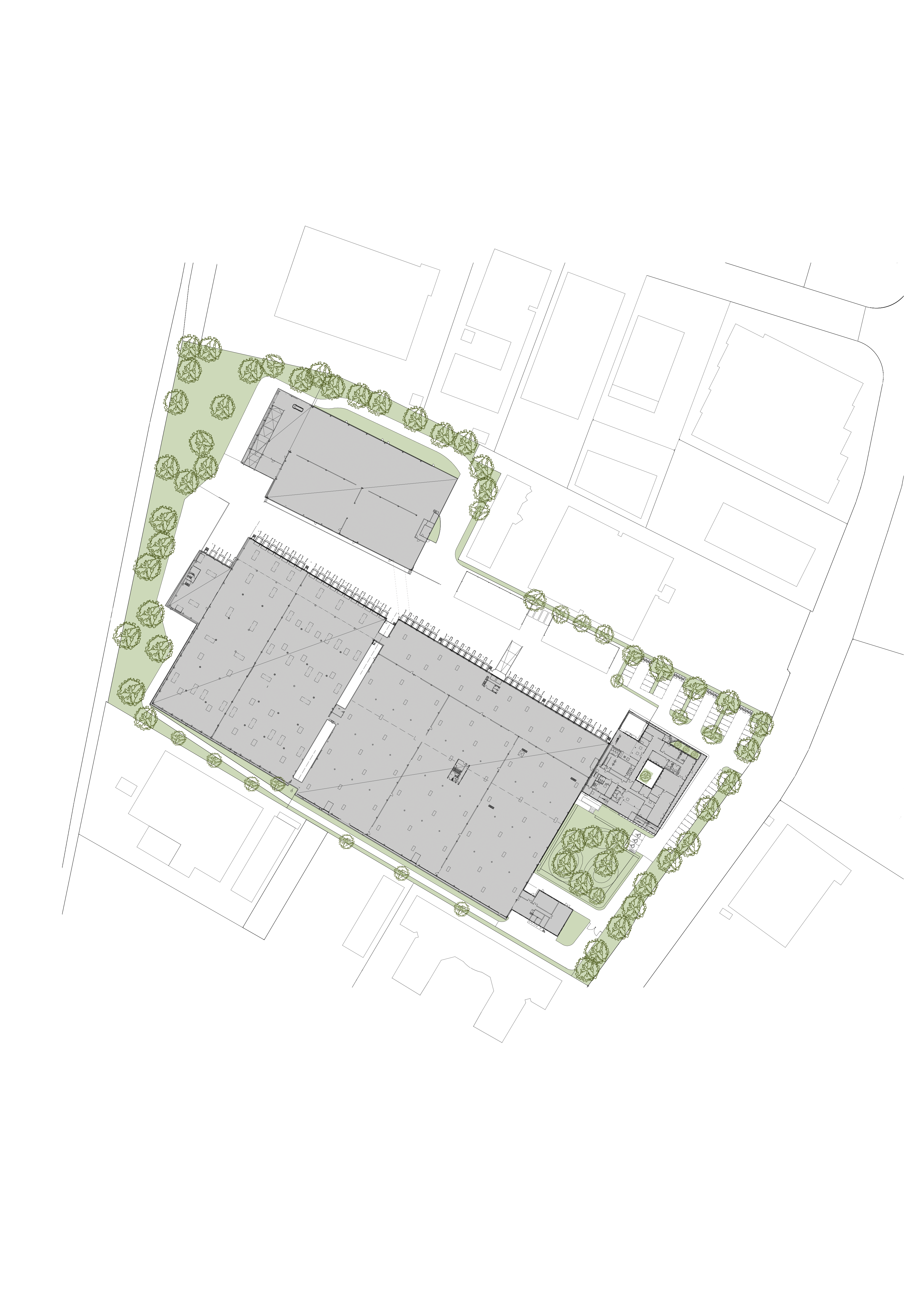

Pfeiffer & May, one of Germany’s leading wholesalers of plumbing and heating technology, was to build a new logistics center at its hub and birthplace in Karlsruhe. An existing property from the 1980s could be taken over that met the client’s requirements and provided expansion opportunities. Analysis of the client’s logistical requirements against the site conditions resulted in minimal intervention in existing areas and buildings.

All other existing buildings were renovated in terms of energy, upgraded structurally and adapted to the client’s new functions and requirements. Part of the roof area was equipped with solar cells that cover the energy needs of the logistics center. The facades were insulated and partly clad with facade panels from the demolition.

The office building needed a complete renovation. The roof was extended and now rests on a new facade structure of vertical frames, which is constructive but also serves as a permanent and maintenance-free sun protection and architectural design element.

As you approach the building, it is a closed monochrome gray facade that slowly opens up to the visitor as you get closer. In some places, larger roof cuts were made for terraces and green areas with trees.

A new hall with a glulam roof frame and green roof complements the existing building and ensures the client’s space requirements.

The former aerosol hall was converted into a block goods and pipe hall with an overhead crane, which presented major structural challenges. The concrete facade elements were sawn out, crushed on site and used as a breakwater in the road construction and in the redevelopment of the courtyard.

The landscape and green areas were redesigned with an infiltration system and stormwater bed for the rainwater from all the halls. and almost a hundred new trees were planted.

The company is gradually transitioning to e-mobility and some ten loading bays are already electrified. The goal is to continue this expansion in parallel with the solar cells, while looking at a solution for our own hydrogen production facility.